The last month of the year provides a good opportunity for UK manufacturers to review health, safety, and environmental (HSE) performance and set the stage for improvement in 2024. Two areas offering relatively straightforward and impactful HSE gains are compressed air systems and metalworking fluids (MWFs). Getting these fundamentals right through enhanced controls can reduce injuries, waste, emissions and costs.

Why Focus on Compressed Air & MWFs?

Compressed air accounts for an average of 10% of a UK manufacturing facility’s electricity consumption, contributing significantly to energy costs and carbon emissions [1]. For example, the Carbon Trust estimates that UK industries spend over £100 million per year powering compressed air systems. MWFs represent 5-15% of all wastes generated by manufacturers [2]. A typical automotive manufacturing plant can use 800,000 litres of MWFs annually and large machining plants may use over 20,000 litres daily. These process utilities also play central roles in safety and environmental management across production lines. Improving monitoring and management of compressed air and MWFs offers a range of HSE and operational benefits:

1. Reduced Injuries

Proper ventilation, fluid containment, and component condition monitoring minimise worker exposure to hazards from airborne oils, and chemical fluid mists. This reduces respiratory issues, chemical burns and other compressed air/MWF-related injuries that affect hundreds of UK workers each year.

2. Optimised Energy Performance

Advanced pressure sensors, acoustic leak detectors, and analytic software allow demand-based control of compressed air supply and precision cooling of MWFs. This cuts waste and electricity usage by 20% or more, saving energy costs.

3. Minimised Fluid Losses & Waste

Sensors that track MWF concentration, bacterial growth, and contamination events in real-time allow highly optimised top-ups with concentrate and fluid changeouts. This reduces fresh fluid purchases by 10-15% annually and lowers hazardous waste disposal volumes. Proper fluid maintenance also prevents production downtimes.

4. Lower Maintenance Costs

Compressed air analytics can quickly flag leaks, moisture issues and equipment faults early via monitoring of pressure fluctuations, dew points and run times. This enables preventive maintenance that reduces downtimes by 30-50% and avoids repair costs.

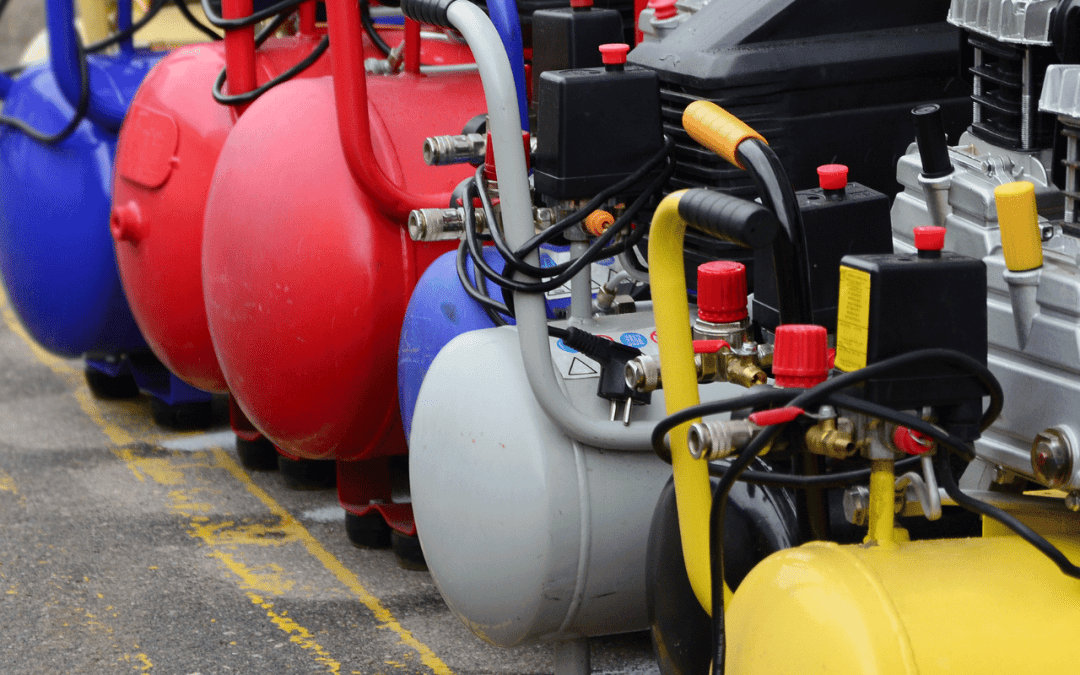

Compressed Air Controls

There are four main areas manufacturers should focus on to improve compressed air management this December:

1. Map Supply & Demand

The first step is thoroughly assessing the compressed air network to identify and map all supplied equipment (compressors, dryers, filters, drains) as well as usage points across the facility, production lines and machines. This mapping allows the optimisation of pressure settings and balancing of supply volumes with actual dynamic production demand.

2. Detect & Repair Leaks

Leaks can account for 20-50% of compressed air consumption. An ultrasonic acoustic leak detector can be used monthly to find and tag leaks. Identified leaks over 1/16th inch should then be repaired within a week.

3. Monitor Oil & Moisture

Installing ISO quality class oil and moisture sensors connected to monitoring software at compressed air entry points and key points of use provides 24/7 data on air quality. Sensor readings should be checked weekly to ensure contamination and moisture levels remain within guidelines to prevent corrosion and product defects.

4. Upgrade Components

Review collected performance data and conduct compressed air system inspections and maintenance record audits to determine where upgrades are needed – additional filtration, larger distribution pipes, improved dryer desiccant, filter changes or heat exchangers. This improves efficiency and reliability.

Metalworking Fluid Controls

There are five important aspects of MWF control to address in December:

1. Standardise Fluids

Reduce the number of speciality MWFs used by thoroughly reviewing machine/operation requirements and consolidating to standardised coolants, lubricants and cleaners. The document recommended applications to simplify usage guidelines, monitoring procedures and waste handling.

2. Automate Concentration Tracking

Inline refractometer sensors connected to a central dashboard automate fluid concentration and quality measurement, eliminating manual test errors while enabling precise, real-time coolant top-ups. This reduces MWF losses by 10% and waste generation.

3. Monitor Microbial Levels

Automated particle counters and image analytic devices like the Foamat system can automatically track foam, bacteria and fungi growth. This allows better timing of biocide additions and fluid change-outs based on microbial colonies versus simple duration targets [3].

4. Improve Containment

Ensure (interlock) machine guards, shielding, and drain trenches fully contain MWF splashes, leaks and discharges. This can help control any potential facility floor safety hazards from slip risks while reducing housekeeping and compliance costs.

5. Standardise PPE

Requirements

Update risk assessments and standardise appropriate PPE like slit/strap shoes, face shields, splash aprons, and respirators for handling specific MWFs. This documents and provides needed protection against fluid contact dangers during mixing, pre/post-process work and equipment maintenance.

The December Opportunity

The year’s end offers a solid 1-2 week window between holiday slowdowns that is ideal for compressed air improvements and MWF control optimisation. Scheduling assessments, leak checks, repairs/upgrades, sensor installations, and fluid consolidation initiatives over this low distraction period set up manufacturing, HSE, and financial performance gains that will benefit the full year ahead.

References

- Carbon Trust (2012). Understanding Compressed Air Systems. https://bit.ly/3XYRUNa

- International Metalworking Fluids Report (2020). https://bit.ly/3EOgRRF

- Format (2023). https://foamat.com